The Importance of Cold Storage Structures for Modern Industries

Home » The Importance of Cold Storage Structures for Modern Industries

Introduction

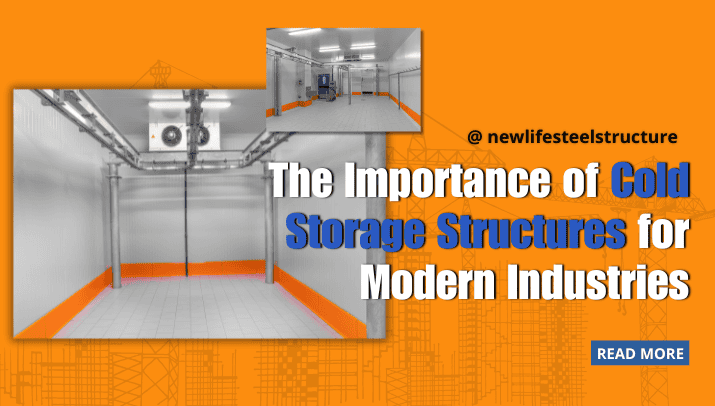

Height Considerations for Pre-Engineered Steel Factory Buildings

Steel factory buildings can be single-story or multi-story, with varying height requirements based on their function. The floor height typically ranges between 6 to 12 meters, depending on industry specifications.

1. Single-Story Steel Factories

Industries that require large equipment, crane beams or heavy machinery, such as metallurgy and heavy machinery manufacturing, often require single-story designs in order to accommodate large-scale equipment installation and operation. These factories typically require a minimum height of 10 meters.

2. Multi-Story Steel Factories

Multi-story factories are commonly used in industries like electronics, pharmaceuticals and consumer goods manufacturing, where equipment is generally compact. The standard floor height in such factories ranges between 6 to 8 meters which gives them adequate operational space.

3. Industry-Specific Height Requirements

– Packaging & Printing Industries require at least 12 meters due to large-scale printing machines.

– Machinery Manufacturing needs at least 10 meters to accommodate production equipment.

– Electronics & Consumer Goods normally maintains a height of 8 meters for efficient workflow.

– Light Manufacturing & Warehouses need a standard height of 6 meters unless specialized storage solutions are required.

Span Considerations for Pre-Engineered Steel Factory Buildings

The span of a steel factory refers to the horizontal distance between two supporting columns which plays an important role in determining space efficiency, layout feasibility and structural stability.

How to Determine the Best Height and Span for a Steel Factory

The ideal design for a pre-engineered steel factory depends on the industry, equipment layout and production needs. Consulting a professional steel structure company like www.newlifesteel.com can help determine the most efficient dimensions while balancing cost-effectiveness and functionality. A strategic design ensures that the factory remains structurally sound, efficient, and adaptable for future expansion.

Conclusion

The height and span of a pre-engineered steel factory directly impact its functionality, production efficiency and overall cost-effectiveness. A well-planned factory design ensures optimal space utilization while meeting the specific needs of different industries. By partnering with experienced steel structure companies, businesses can create tailored solutions that maximize efficiency, reduce operational costs and support long-term growth.